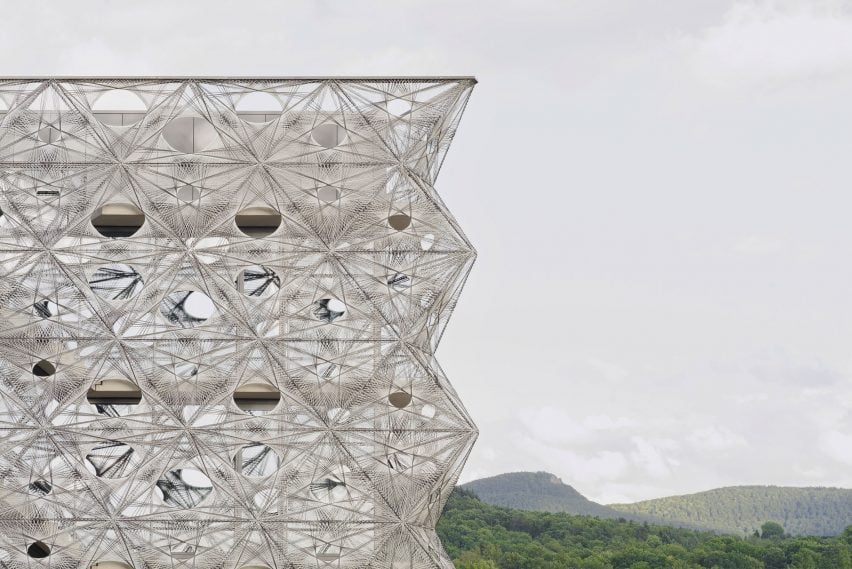

An online of glass and carbon fibres envelops Texoversum, a college constructing for textiles that structure studios Allmannwappner and Menges Scheffler Architekten have created in Germany.

Positioned within the metropolis of Reutlingen, Texoversum types a part of the Reutlingen College of Utilized Sciences campus enlargement and accommodates places of work, workshops, a college retailer, collaboration areas and a CNC robotic workspace.

Its woven facade design is knowledgeable by textile building and was developed by Allmannwappner and Menges Scheffler Architekten with engineering observe Jan Knippers Ingenieure.

“The fibre facade is an integral a part of each the architectural expression of the constructing as a textile analysis and innovation centre and the environmental engineering and associated indoor consolation technique of the venture,” Menges Scheffler Architekten companion Achim Menges informed Dezeen.

Texoversum’s facade consists of triangular panels measuring roughly 4 metres in width and 1.5 metres in top, every made by a robotic winding course of developed on the College of Stuttgart.

There are 5 varieties of panels, every sharing the identical triangular outer form however various barely to create nook items and different-sized openings within the centre.

Manufactured by FibR GmbH, the web-like panels are created from white glass fibres overlayed with black carbon fibres that add structural assist.

Because the manufacturing is bespoke, no manufacturing waste or materials off-cuts have been produced, in keeping with Menges.

“Fibrous filaments are freely positioned between two rotating winding scaffolds by a robotic,” defined Menges. “Throughout manufacturing, a lattice of white glass fibres is generated, onto which the black carbon fibres are positioned the place they’re structurally wanted.”

“On this course of, the predefined form of the constructing element emerges solely from the interplay of the filaments, eliminating the necessity for any mould or core,” continued Menges.

He mentioned this course of leads to a “bespoke type” and a “extremely distinct architectural look” for every element.

Texoversum’s facade tiles, that are self-supporting, have a staggered association. This creates a multi-layered impact that shades the interior areas whereas additionally offering openings with views out of the constructing.

“The fibre facade constitutes the exterior solar safety of the constructing, which has to fulfil stringent shading necessities in compliance with the German constructing code,” mentioned Menges.

“The white glass fibres function a formwork for the black carbon fibres, which offer the required structural capability,” added structural engineer Jan Kippers.

“It’s a pure fibre construction that spans from flooring to flooring and permits cantilevers of round 4 metres on the higher edge with no metal body or related.”

Inside, Texoversum has a split-level design. A central atrium separates the constructing into two halves, with either side separated in top by a half-floor degree.

It has an industrial inner look with an uncovered concrete construction and ceiling ductwork and an open-plan format to encourage collaborative working.

The robotic winding course of used for the facade has beforehand been utilized in designs for pavilions together with the Elytra Filament Pavilion at London’s V&A museum and the BUGA Wooden Pavilion on the Bundesgartenschau horticultural present in Germany.

In keeping with Menges, Texoversum was the primary time the robotic manufacturing course of was applied within the design of a everlasting constructing.

“Whereas we had efficiently constructed a number of momentary constructions earlier than, Texoversum constitutes the primary everlasting constructing utilizing this design and manufacturing method,” he mentioned.

“As Texoversum is a everlasting constructing, we needed to meet the total necessities of German constructing authorities,” added Kippers.

“For this, in depth checks needed to be carried out to show the long-term creep behaviour, climate resistance, hearth resistance and others.”

Different buildings with facades made by robots embrace an artwork gallery in Shanghai’s West Bund district by Archi-Union Architects and a vineyard in France’s Rhône Valley by Carl Fredrik Svenstedt Architect.

The pictures is by Brigida González.